Product description

Product Name: Full-Automatic Vacuum Defoaming Mixer (Planetary Centrifugal Technology)

Key Features and Specifications

| Feature Category | Specification |

| Mixing Principle | Planetary Centrifugal Motion (Rotation and Revolution) |

| Key Function | Mixing and Simultaneous De-aeration/Defoaming |

| Vacuum System | Integrated high-vacuum chamber (Crucial for removing micro-bubbles) |

| Speed Control | Independently adjustable speeds for Rotation and Revolution |

| Material Handling | Capable of mixing high-viscosity pastes, slurries, and thixotropic materials |

| Operational Mode | Non-contact stirring (no blades or mechanical shaft) in sealed containers |

| Capacity | Available in various volumes, from lab-scale (e.g., 50g) to production-scale (e.g., 5 kg) |

Product Summary

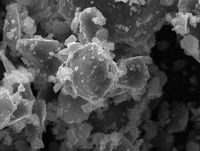

The Vacuum Defoaming Mixer is a highly specialized piece of Precision Instrumentation designed to prepare materials that require exceptionally uniform mixing and a complete absence of air bubbles. Utilizing planetary centrifugal motion under a high vacuum environment, this mixer delivers powerful, thorough, and rapid homogenization for a wide range of materials, including pastes, adhesives, ceramics, and chemical slurries.

This equipment is critical in high-specification manufacturing and advanced research where even micro-bubbles can compromise material performance, such as in electronics, advanced batteries, and high-quality coatings.

Primary Applications

New Energy Research:

Battery Electrode Slurries: Essential for preparing high-solids-content battery cathode and anode slurries (like Li-ion and solid-state battery formulations) to ensure high density, uniformity, and prevent defects caused by trapped air bubbles in the final electrode film.

Sealant and Electrolyte Mixing: Used for bubble-free mixing of highly viscous electrolyte gels and sealing materials.

Materials Chemistry & Functional Surfaces:

High-Purity Composites: Mixing and de-aerating sensitive or costly raw materials, such as conductive inks, ceramic precursors, and high-performance polymer composites.

Adhesives and Encapsulants: Preparing bubble-free potting compounds, resins, and medical-grade adhesives, which require flawless homogeneity and no voids for structural integrity.

Polymers & Biomaterials:

Viscous Formulation: Efficiently mixing high-viscosity polymers and masterbatches with fillers and additives, which are typically difficult to process with traditional stirrers.

Advantages for Advanced Manufacturing

Bubble-Free Results: The combined effect of centrifugal force and vacuum ensures the complete removal of air, leading to higher material density and superior performance.

Contamination-Free: Mixing is performed in the user’s own sealed container (e.g., centrifuge tube, syringe, beaker), eliminating cross-contamination and the need for frequent cleaning.

High Efficiency: Capable of achieving complete homogenization and de-aeration in minutes, significantly accelerating research and production cycles.

Ordering and Consultation

As a specialized tool, we offer models tailored to your specific viscosity and volume requirements.

Request a Quote: Specify your required mixing capacity and maximum viscosity for a customized solution.

Expert Support: Our technical team is available to help you integrate this mixer into your existing material preparation protocols for applications like electrode fabrication.