Product description

Product Name: Digital Rotational Viscometer for Adhesives and Coatings (Precision Rheometer)

Key Features and Specifications

| Feature Category | Specification |

| Measurement Principle | Rotational Viscometry (Measures torque required to rotate a spindle in a fluid) |

| Viscosity Range | Wide range coverage (e.g., 1 mPa·s to 13 million mPa·s) using multiple spindles |

| Display | Digital LCD Screen (Real-time display of viscosity, shear rate, shear stress, temperature, and speed) |

| Speed Range (RPM) | Variable speed settings (e.g., 0.3 to 100 RPM) for measuring Non-Newtonian behavior |

| Spindles | Supplied with a complete set of standard spindles (e.g., L series or R series) |

| Accuracy | High precision (e.g., ± 1.0% of full scale range) |

| Connectivity | Data output port (e.g., USB) for PC connection and data logging |

Product Summary

The Digital Rotational Viscometer is a cornerstone piece of Precision Instrumentation for Quality Control and research in the Polymers & Biomaterials and Materials Chemistry sectors. It provides highly accurate and reproducible measurements of a fluid’s viscosity—a critical parameter for determining material performance, application characteristics, and product consistency.

Unlike simple flow cups, this rotational viscometer utilizes a set of calibrated spindles rotating at precisely controlled speeds to measure dynamic viscosity and is essential for characterizing complex Non-Newtonian fluids like adhesives, paints, coatings, resins, and inks.

Primary Applications

Polymers & Coatings (Adhesives, Paints, Resins):

Quality Control: Rapidly verify the consistency and batch-to-batch uniformity of final products and raw materials.

Application Testing: Determine flow characteristics such as thixotropy (shear thinning) and yield stress, which dictate how a coating will behave during spraying, dipping, or brushing.

Formula Development: Precisely measure the impact of additives, fillers, and temperature on material flow properties.

Materials Chemistry & Suspension Science:

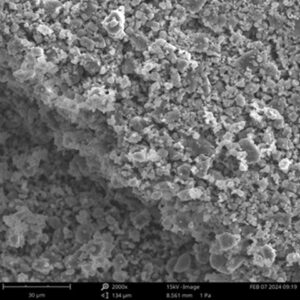

Slurry Characterization: Analyze the stability and flow of high-solids-content slurries used in electrode manufacturing, ceramic forming, and chemical processing.

Rheological Studies: Conduct advanced rheological measurements to understand the fundamental mechanical behavior of semi-solids and complex fluids.

Advantages for Professional Users

Ease of Use: User-friendly digital interface allows for rapid setup and operation, minimizing training time.

Comprehensive Data: Provides more than just a single viscosity number; it offers a detailed rheological profile essential for high-performance formulation.

Temperature Ready: Many models include or are compatible with a dedicated temperature bath/probe, allowing for viscosity measurement under controlled conditions, which is crucial for temperature-sensitive materials.