Product description

Product Name: Small-Capacity Benchtop Ethylene Oxide (EtO) Sterilizer

Key Features and Specifications

| Feature Category | Specification |

| Sterilization Agent | Ethylene Oxide (EtO) Gas (EO/EOG) |

| System Type | Low-Temperature Gas Sterilizer |

| Capacity | Small Volume (Typically 25 L to 100 L Chamber Volume) |

| Sterilization Cycle | Full Cycle (Pre-conditioning, Gas Exposure, and Aeration/Degassing) |

| Temperature | Low Temperature (Typically 30°C to 55°C), suitable for heat-sensitive materials |

| Safety | Integrated Ventilation/Aeration System, Gas Leak Alarm, and Safety Monitoring |

| Material Compatibility | Excellent for sterilization of heat-sensitive polymers, medical devices, and complex equipment |

| Control | Microprocessor Control with digital display and printable cycle records |

Product Summary

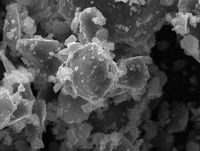

The Small-Sized Ethylene Oxide (EtO) Sterilizer is a specialized piece of Precision Instrumentation used for the safe and effective sterilization of materials and equipment that cannot withstand high temperatures or moisture (e.g., autoclaving). EtO is a powerful gaseous sterilant that is highly effective at penetrating surfaces and destroying microorganisms, even in complex or tightly packaged items.

This benchtop unit is designed to provide a reliable, low-temperature sterilization cycle within a compact laboratory footprint. Its crucial features include precise control over gas concentration, humidity, and temperature, followed by a mandatory aeration phase to ensure the safe removal of residual EtO gas.

Primary Applications

Biochemical / Life Sciences:

Sterilization of Sensitive Equipment: Ideal for sterilizing complex instruments, plastic consumables, sensitive electronic components, and packaged medical devices that would be damaged by steam or high heat.

Biomaterial Preparation: Sterilizing polymer scaffolds, filtration membranes, and specialized labware used in cell culture and tissue engineering where material integrity is paramount.

Polymers & Biomaterials:

Material Testing: Sterilizing samples of heat-sensitive polymers and plastics before mechanical or chemical testing to ensure the sterilization process does not alter material properties.

General Laboratory Use:

Customized Instruments: Used for sterilizing custom-made tools, sensors, and equipment that do not have standard sterilization protocols.

Safety and Operation

Low-Temperature Process: The gentle, low-temperature cycle minimizes the risk of damage, deformation, or degradation of sensitive materials, unlike high-heat methods.

Integrated Safety: Due to the hazardous nature of EtO, this sterilizer includes robust safety features, including automated cycle control, continuous air monitoring, and a critical aeration (degassing) phase to eliminate EtO residue before materials are handled.

Regulatory Compliance: Essential for laboratories requiring compliance with sterilization standards for materials intended for in-vivo or medical applications.