Product description

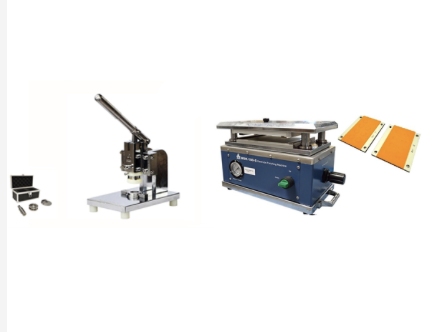

Product Name: High-Precision Electrode Slitting Machine (Battery Pole Piece Slitter)

Key Features and Specifications

| Feature Category | Specification |

| System Type | Precision Slitting/Cutting Equipment |

| Function | Longitudinal Slitting of large-format coated electrode sheets into narrow, highly accurate strips (Pole Pieces) |

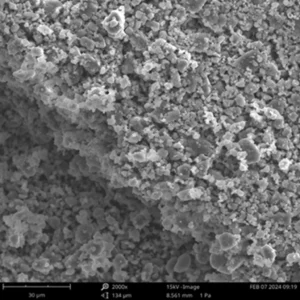

| Material Handling | Suitable for slitting Anode (Copper/Active Material) and Cathode (Aluminum/Active Material) electrode foils |

| Slitting Method | Rotary Blade or Razor Blade Slitting (High-precision shear cutting) |

| Slitting Width | Highly customizable with Micro-Level Tolerance (Critical for subsequent winding/stacking) |

| Tension Control | Advanced Unwinding and Rewinding Tension Control (Ensures uniform material pull without stretching or wrinkling) |

| Key Advantage | High Accuracy and Edge Quality (Minimizes burrs which can cause internal short-circuits) |

Product Summary

The Battery Pole Piece Slitter is an indispensable piece of Precision Instrumentation in the New Energy Research and battery manufacturing chain. Its function is to take large, master rolls of coated and calendered battery electrode material and precisely cut them into the narrow, uniform strips (pole pieces) required for final cell assembly (winding for cylindrical/prismatic cells or stacking for pouch cells).

The extreme accuracy of this process is paramount. Any deviation in width or the presence of rough edges (burrs) can lead to misalignment in the cell core or, more dangerously, penetrate the separator and cause an internal short-circuit, severely compromising cell safety and cycle life. This machine provides the necessary high-precision, clean-cut, and uniform tension essential for high-performance battery production.

Primary Applications

New Energy Research:

Electrode Preparation: A crucial, final step in electrode processing before cell assembly. The machine determines the exact width of the final electrode pieces that will form the core of the battery.

R&D and Pilot Line: Used to quickly produce small batches of various width electrodes for testing different cell formats and optimizing electrode-to-case fitment.

Quality Control:

Edge Inspection: High-quality slitters are designed to produce a near-perfect edge, which is continuously monitored to ensure burr-free production and prevent manufacturing defects.

Precision and Performance

Tension Control: Independent, closed-loop tension control systems on the unwinding and rewinding stations ensure the delicate electrode material is handled consistently, preventing the material from stretching, which would distort its density and performance.

Dust/Contamination Control: Designed with specialized systems to minimize carbon/active material dust generation during the cutting process, maintaining a clean environment critical for battery manufacturing.

Customization: The slitting knife system is adjustable to produce multiple pole-piece widths from a single master roll, offering great flexibility for R&D.