Product description

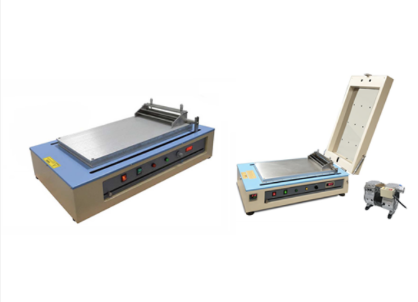

Product Name: Laboratory/Pilot-Scale Precision Electrode Coating Machine

Key Features and Specifications

| Feature Category | Specification |

| System Type | Precision Film Coating Equipment |

| Function | Uniform, Controlled Deposition of Electrode Slurry onto a Metal Foil Current Collector |

| Coating Method | Transfer Coating (e.g., Doctor Blade, Comma Coater, Slot-Die Coating) |

| Substrates | Compatible with Copper (Cu) Foil (Anode) and Aluminum (Al) Foil (Cathode) |

| Coating Thickness | Precision Gap/Blade Adjustment (Micron-level accuracy, crucial for performance) |

| Drying Method | Integrated Heating and Drying System (Uniform temperature control for solvent removal) |

| Coating Modes | Continuous or Intermittent (Gap) Coating (Essential for tab areas) |

| Key Advantage | High Consistency and Uniformity of the electrode film layer |

Product Summary

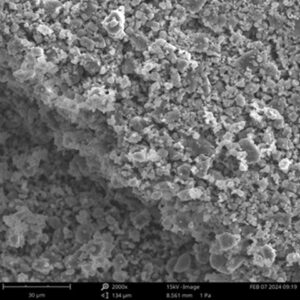

The Electrode Coating Device is a critical piece of Precision Instrumentation in the New Energy Research process, specifically for the fabrication of lithium-ion and other advanced secondary batteries. This equipment is responsible for the uniform application of the electrode slurry (a mixture of active material, conductive additives, and binder in a solvent) onto a metallic foil current collector.

The quality of the coating is a primary determinant of the final battery cell’s performance, capacity, and life cycle. Non-uniformity in the coated film can lead to uneven current distribution, localized heating, and premature capacity fade. Our precision coating device provides micron-level control over the thickness and width of the coated film, ensuring a consistent, high-quality electrode for reliable cell testing and pilot production.

Primary Applications

New Energy Research:

Electrode Fabrication: A mandatory step in the production of high-performance battery electrodes (anodes and cathodes) for pouch, cylindrical, and prismatic cells.

Slurry Optimization: Used to test and validate different electrode slurry formulations and rheological properties under controlled coating parameters.

Novel Material Synthesis: Ideal for coating new active materials, solid-state electrolyte films, or catalyst layers onto substrates with high precision.

Materials Chemistry & Functional Surfaces:

Functional Film Production: Used for coating various thin films, pastes, or adhesives onto flexible substrates for research in electronics, smart materials, or solar cells.

Precision and Customization

Gap Control: The heart of the machine is its ability to precisely adjust the distance between the coating blade/die and the current collector, ensuring the desired wet film thickness and dry mass loading.

Drying Zone: The integrated heating and drying zone features highly uniform temperature distribution and controlled air flow to remove solvent rapidly and consistently, preventing cracking or delamination of the electrode film.

Scale: Available in small-scale benchtop models for R&D (often manual or semi-automatic) and larger pilot-scale roll-to-roll (R2R) systems for larger production volumes.

Intermittent Coating: Allows for the uncoated sections necessary for the current collector tab (where the electrical connection is made), maximizing usable electrode area and production efficiency.