Product description

Product Name: Standard and Custom-Designed Battery & Capacitor Cell Cases

Key Features and Specifications

| Feature Category | Specification |

| Material Types | Aluminum (Al), Stainless Steel (SS), Nickel-Plated Steel, and Polymer Laminate Film |

| Case Formats | Cylindrical (Can/Shell), Prismatic (Box), and Pouch (Laminate Film) |

| Key Function | Containment, Protection, and Electrical Insulation/Connection |

| Sealing | High-precision sealing surfaces for hermetic, leak-proof closure |

| Tolerance | Highly controlled Dimensional Tolerance (Critical for automated assembly) |

| Wall Thickness | Optimized for mechanical stability and energy density |

| Safety Features | Options include Pressure Relief Vents (for cylindrical and prismatic cells) |

Product Summary

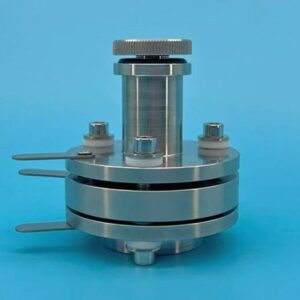

Battery and Capacitor Cases are the foundational structural components that encapsulate the active elements of an energy storage cell. They serve the critical function of providing mechanical protection against external damage, preventing electrolyte leakage, and isolating the cell components from the ambient atmosphere (especially moisture and oxygen).

Available in various formats to support different cell designs—from the high-energy-density Pouch Film to the structurally robust Cylindrical and Prismatic Cans—these cases are manufactured with high-purity, corrosion-resistant materials to ensure the long-term stability and safety of the electrochemical system.

Primary Applications

New Energy Research:

Cell Prototyping: Supplying standard and custom cases (e.g., Coin Cells, cylindrical cans) for fabricating and testing new electrode materials and electrolyte systems on a small scale.

Full-Cell Assembly: Providing high-volume aluminum laminate film and engineered prismatic or cylindrical shells for pilot-scale manufacturing of commercial battery cells.

Supercapacitors: Supplying robust, sealable cases required for high-power, high-cycle-life capacitor designs.

Materials Chemistry & Quality Control:

Standardized Testing: Offering standardized case formats (e.g., CR2032 coin cells) to ensure highly reproducible electrochemical testing across different labs and research groups.

Material Compatibility: Using specialized materials (e.g., high-grade Stainless Steel) for testing highly corrosive or novel electrolyte systems.

Formats and Selection

Cylindrical Cells (Cans): Offer excellent mechanical strength and internal pressure resistance. Common for both Li-ion and traditional primary batteries.

Prismatic Cells (Boxes): Efficiently pack into battery modules and are often used in automotive and stationary storage applications where space utilization is critical.

Pouch Cells (Laminate Film): Offer the best gravimetric and volumetric efficiency, providing a flexible, lightweight solution for consumer electronics and custom designs. Requires the use of a Battery Packaging Machine (Sealer) for final closure.