Product description

Product Name: Specialized Components for Lithium-Sulfur (Li-S) Battery Systems

Product Summary

Our Lithium-Sulfur (Li-S) Battery Research Materials portfolio is dedicated to supporting the development of this next-generation energy storage technology. Li-S batteries hold immense promise due to the incredibly high theoretical specific energy density (over 2500 Wh/kg), driven by the use of a lightweight Sulfur cathode and a Lithium metal anode.

We supply advanced, high-purity materials specifically engineered to combat the major challenges inherent in Li-S systems, primarily the polysulfide shuttle effect and the instability of the lithium metal anode. Our materials help researchers achieve breakthroughs in cycle stability, Coulombic efficiency, and practical energy density.

Key Material Categories

| Category | Examples | Role in the Battery System |

| Cathode Active Material | High-Purity Sulfur Powder, Sulfur/Carbon Composite materials | The Charge Storage Medium (High theoretical capacity of 1675 mAh/g). |

| Anode Material | High-Purity Lithium Metal Foil (Li-foil), Protected Li Anode (PLA) precursors | The Counter Electrode (Lightest metal anode, providing the capacity source). |

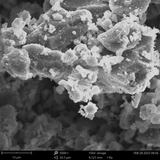

| Polysulfide Mitigation | Specialized Carbon Hosts (Porous Carbons, Hollow Spheres), Metal Oxide/Sulfide Coatings (e.g., TiO₂, V₂O₅) | Physical and Chemical Trapping of soluble polysulfides (Intermediates of the discharge reaction). |

| Electrolyte System | Solvents (e.g., DOL/DME blends), Lithium Salts (e.g., LiTFSI, LiNO₃ additive) | Ion Transport Medium (Formulations are crucial for polysulfide solubility control). |

| Separators | High-density Polymer Membranes, Functionalized Interlayers (coated separators) | Physical Barrier with added Polysulfide Barrier functionality. |

Primary Applications

High-Energy Density Development:

Cathode Formulation: Research into confining sulfur within carbon structures to improve electron conductivity and prevent polysulfide dissolution.

Anode Protection: Development of stable electrolyte/anode interphases to suppress dendrite growth and consumption of the lithium metal.

Cycle Stability Studies:

Interlayer/Separator Engineering: Using functionalized carbon or metal oxide interlayers between the separator and cathode to act as a polysulfide reservoir and reaction site, reducing shuttle loss.

Electrolyte Optimization:

Formulating electrolytes with specific additives (like LiNO₃) to stabilize the lithium metal anode and suppress the shuttle phenomenon, which directly impacts cell life.

Technical Significance

The core challenge in Li-S research is maintaining the integrity of the cell over hundreds of cycles. The materials we supply are selected for their ability to:

Host Sulfur: Materials with high porosity and optimized surface chemistry to physically and chemically immobilize the active sulfur species.

Stabilize Lithium: Foils and specialized salts that promote the formation of a stable, ionically conductive, and electronically insulating Solid Electrolyte Interphase (SEI) on the Li metal surface.

Ordering and Consultation

We offer a focused selection of high-purity chemicals and structured carbon hosts.

Expert Support: Our technical specialists can guide you in selecting the right electrolytes and additives critical for achieving stable cycling in your Li-S prototype, ensuring you address the complex challenges of this high-potential chemistry.

Flexible Supply: Available in research-grade quantities for lab-scale prototyping (Coin Cells) and larger volumes for pilot manufacturing.