Product description

Solid State Round Cell Battery Testing Mold

The Solid State Round Cell Battery Testing Mold is a precision-engineered tool designed for advanced research and development of next-generation solid-state battery prototypes. It provides controlled, high-pressure assembly essential for evaluating novel solid polymer electrolytes, like PEO-PLA blends, and their electrochemical performance.

Key Features & Benefits

Standard 13mm Format: Compatible with common laboratory setups for seamless integration into existing testing workflows.

Precision Sealing Mechanism: Features a ¼-inch square drive electronic torque system, engineered to apply and maintain a consistent, high sealing pressure of 4 bar. This is critical for optimizing the interface between solid electrolyte and electrode materials.

Open Spanner Compatibility: Designed for straightforward assembly and disassembly using standard tools, facilitating efficient prototype iteration.

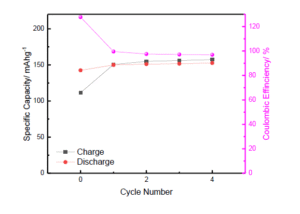

Enhanced Performance Validation: As demonstrated in testing, prototypes assembled under 4-bar pressure in this mold showed superior discharge capacity compared to conventional setups (e.g., standard EL-Cells), directly enhancing the electrochemical performance of the cell materials.

Technical Validation & Application

This mold was instrumental in the electrochemical testing of a novel LFP||PEO-PLA||Li solid-state prototype. Testing confirmed that the fixed high-pressure environment significantly improves interfacial properties, leading to near-theoretical discharge capacity from the cathode material. It is the ideal solution for researchers and engineers developing and validating solid polymer electrolytes, nanocomposites, and other advanced materials for solid-state battery applications.

Electrochemical test of New Prototype of Solid-State 2 Electrode Cell prototype

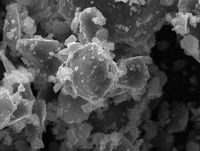

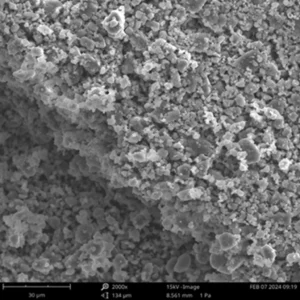

The prototype cell was assembled using, as solid polymer electrolyte, a self-standing, mechanically resilient membrane composed of a Polyethylene Oxide–Poly Lactic Acid (PEO–PLA) blend. The cell configuration was LFP || PEO-PLA || Li, with a low-loading LFP cathode of

3.4 mg. The cell was sealed at 4 bar and subsequently tested through rate-capability measurements at 70 °C.

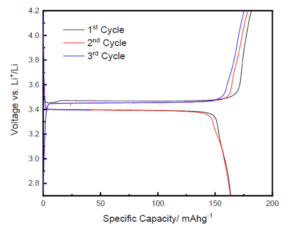

The first 2–3 voltage profiles are reported below. As can be observed, the data exhibit the typical electrochemical signature of LFP. However, the first three charge cycles show capacities exceeding the theoretical capacity of LFP. This behaviour is not related to the prototype cell itself but is attributed to the presence of a monomer impurity within the tested membrane, which is progressively consumed during the charges. The presence of this impurity is further confirmed by the characteristic bump observed in the first charge cycle.

Despite the charging issue, the cell delivered a near-theoretical discharge capacity.

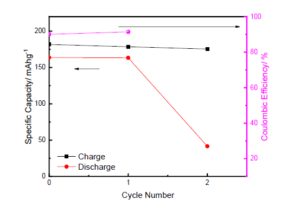

To highlight the advantages of the proposed cell prototype over a conventional EL-Cell, a reference cell was assembled using the same materials. Although the membrane exhibited the same charging-related issue, the reference cell delivered an overall lower discharge capacity. This result indicates that sealing the prototype cell at a fixed pressure of 4 bar significantly enhances the interfacial properties, leading to improved electrochemical performance of the materials.