Product description

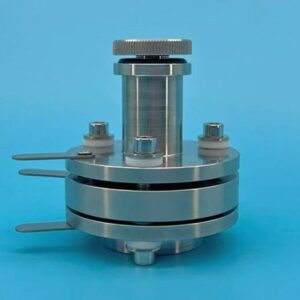

Product Name: Semi-Automatic or Full-Automatic Pouch Cell Battery Packaging/Sealing Machine

Key Features and Specifications

| Feature Category | Specification |

| System Type | Precision Heat Sealing/Packaging Equipment |

| Function | Vacuum Sealing and Final Sealing of Pouch Type Battery Cells |

| Sealing Method | Heat Sealing (Constant or Impulse Heat) |

| Temperature Control | High-precision PID temperature control (Ensures consistent, reliable seals) |

| Sealing Head | Customizable molds for various pouch sizes and shapes |

| Vacuum Function (Optional) | Built-in Vacuum Chamber for de-gassing and vacuum packaging before final seal |

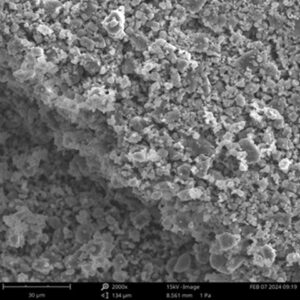

| Material Handling | Suitable for sealing aluminum-laminated film for Pouch Cells |

| Key Advantage | High Sealing Strength and Airtight Integrity for cell life |

Product Summary

The Battery Packaging Machine is a piece of Precision Instrumentation and essential manufacturing equipment for laboratories and pilot lines engaged in the fabrication of Pouch Type Lithium-ion (Li-ion) and solid-state batteries. Its primary function is to create a robust, hermetic seal on the aluminum-laminated film that encapsulates the electrode stack and electrolyte.

The equipment is crucial because the longevity and safety of a battery cell are directly dependent on the integrity of its seal. Models often feature a vacuum chamber to perform a degassing step (removing residual gases and air after electrolyte filling) before performing the final, airtight package sealing.

Primary Applications

New Energy Research:

Pouch Cell Fabrication: A core piece of equipment for all R&D and pilot lines manufacturing flexible or custom-shaped pouch cells, essential for sealing after the electrode stacking and electrolyte injection processes.

Solid-State Battery Assembly: Used for sealing advanced solid-state or semi-solid battery prototypes that require a highly stable, air-free, and moisture-free environment.

Degassing Process: The vacuum sealing function is vital for removing gaseous byproducts formed during the initial charge/discharge (formation) cycle, enhancing cell performance and safety.

Materials Chemistry & Quality Control:

Seal Integrity Testing: Used to ensure the sealing quality and integrity of new laminated films or packaging materials under various temperature and pressure conditions.

Models and Customization

Semi-Automatic (Lab-Scale): Manual placement of the cell followed by automatic vacuum and heat sealing. Ideal for R&D where flexibility and material changeovers are frequent.

Full-Automatic (Pilot-Scale): Integrated system for higher throughput, often including automatic loading/unloading and multi-position sealing for large-volume pilot runs.

Customization: Sealing jaw dimensions and mold shapes are customizable to perfectly match the design and size of your specific pouch cell prototype.

Expert Support: Our technical team provides consultation on optimizing sealing temperature, pressure, and time parameters for various aluminum-laminated film thicknesses and electrolyte types.