Product description

Product Name: High-Precision Battery Testing System (Charge/Discharge Cycle Analyzer)

Key Features and Specifications

| Feature Category | Specification |

| System Type | Multi-Channel Electrochemical Analyzer |

| Function | Charge/Discharge Cycling, Capacity Measurement, and Life Cycle Testing |

| Channel Count | Available in various channel numbers (e.g., 8, 16, 32, or more) |

| Current Range | Wide range (e.g., µA to 100 A), adaptable for coin cells, pouch cells, and large-format packs |

| Voltage Range | Highly precise control and measurement (e.g., 0 V to 5 V or higher) |

| Accuracy | High Current and Voltage measurement accuracy (Typically ± 0.05% of Full Scale) |

| Software | Professional software for custom protocol programming, real-time data monitoring, and post-test data analysis |

| Key Advantage | Reliable and Reproducible testing of energy storage performance |

Product Summary

The Battery Testing Equipment (or Battery Analyzer) is the definitive piece of Precision Instrumentation for all New Energy Research. This system is an essential tool for evaluating the performance, efficiency, life cycle, and safety of single cells or battery packs under precisely controlled electrical conditions.

It functions as a highly accurate, multi-channel potentiostat/galvanostat, capable of performing complex sequences of charging and discharging at specific currents (C-rates) or voltages. The sophisticated software allows researchers to design, execute, and analyze customized test protocols, providing the critical data needed to validate and improve new electrode materials, electrolytes, and cell designs.

Primary Applications

New Energy Research:

Life Cycle Analysis (Cycling): Determining the long-term capacity retention and lifespan of battery cells under defined operating conditions.

Rate Capability Testing: Measuring cell performance at various charge/discharge rates (C-rates) to assess power capability and internal resistance.

Efficiency Calculation: Precisely measuring Coulombic Efficiency (CE) and energy efficiency, which are key metrics for fundamental material performance.

Materials Chemistry & Functional Surfaces:

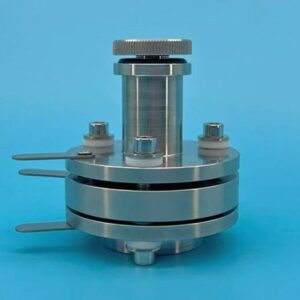

New Material Validation: Used for the initial electrochemical screening of novel anode and cathode powders (e.g., silicon, lithium-sulfur, or solid-state materials) in coin cells or Swagelok cells.

Quality Control:

Batch Testing: Used in pilot lines to test and grade manufactured cells for consistency, quality assurance, and compliance with performance specifications.

Models and Expandability

Multi-Channel Design: The independent channel design allows simultaneous testing of numerous cells or cell prototypes under different conditions, maximizing throughput and accelerating R&D.

Auxiliary Features: Advanced models include options for temperature monitoring (thermocouples) and auxiliary voltage monitoring (reference electrode connection) for deeper cell diagnosis.

Expandable Current Ranges: Systems are available with highly specific current modules, ranging from micro-ampere resolution (for leakage or solid-state battery testing) up to high-current modules for large-format pouch and cylindrical cells.

Integration: Compatible with environmental chambers (e.g., Thermal Chambers) to perform testing at controlled high or low temperatures, crucial for understanding real-world battery performance.