Product description

Product Name: Laboratory/Pilot-Scale Rolling Mill (Cold or Hot Operation)

Key Features and Specifications

| Feature Category | Specification |

| System Type | Precision Rolling/Pressing Equipment |

| Model Variants | Cold Rolling Mill (Room Temperature) or Hot Rolling Mill (High-Temperature Capability) |

| Function | Controlling and Reducing the Thickness of Sheet Materials (Foils, Electrodes, Metals) |

| Rolling Method | Two-Roll (Double-Roller) Precision Gap Adjustment |

| Roller Material | High-Hardness, High-Precision Alloy Steel |

| Roller Accuracy | High Parallelism and Concentricity Tolerance (Crucial for uniform thickness) |

| Thickness Control | Digital Display or High-Precision Micrometer/Dial Gauge for gap setting |

| Motorization | Electric Motor Drive with adjustable speed and high torque transmission |

| Key Advantage | Densification and Uniform Thickness for high-performance materials |

Product Summary

The Rolling Mill is a foundational piece of Precision Instrumentation in New Energy Research and Materials Chemistry used for material densification and dimension control. It utilizes a powerful set of rotating rollers to compress sheet materials, reducing their thickness while simultaneously increasing their density and surface quality.

These mills are categorized by their operating temperature:

Cold Rolling Mill: Operates at room temperature, ideal for materials that do not require high heat treatment or that would degrade under high temperatures (e.g., final battery electrodes).

Hot Rolling Mill: Features a heating system (often integrated with the rollers or surrounding chamber) to pre-heat the material, which is necessary for increasing the material’s ductility and facilitating the rolling of brittle metals, ceramics, or high-viscosity polymers.

Primary Applications

New Energy Research:

Battery Electrode Densification: Absolutely essential for Cold Rolling battery electrodes (cathode and anode sheets) after coating and drying to achieve the optimal porosity and density. This process is crucial for maximizing volumetric energy density and improving electrical conductivity.

Current Collector/Metal Foils: Used in Hot or Cold Rolling to control the thickness of metallic foils (e.g., copper, aluminum, nickel) used as current collectors.

Materials Chemistry & Functional Surfaces:

Thin Film/Foil Production: Manufacturing thin sheets of metal alloys, composite materials, or ceramics with highly uniform thickness for R&D purposes.

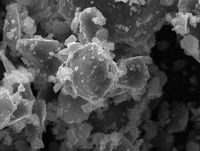

Powder Consolidation: Compacting powder layers or green sheets into dense bodies before sintering or further processing.

Polymers & Biomaterials:

Film Extrusion Refinement: Calibrating and refining the thickness and surface finish of polymer films or sheets.

Considerations for Selection

Hot Rolling Capability: Select a Hot Rolling Mill if your material requires elevated temperatures (e.g., above the recrystallization temperature of a metal) to improve material flow, prevent cracking, and increase ductility during compression.

Roller Width: Available with various roller widths to accommodate the size of your material sample or pilot-scale electrode sheet.

Precision: Look for models with micrometer-level gap adjustment and robust frames to ensure high-precision, uniform pressure and minimal roller deflection during high-load rolling.