Product description

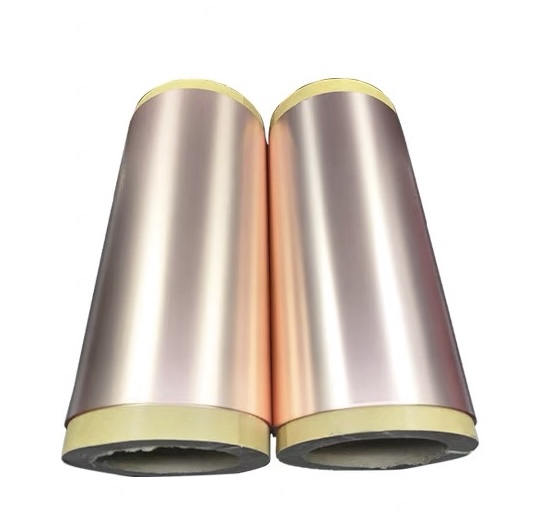

Product Name: High-Purity Metal Foils (Current Collector Grade)

Key Features and Specifications

| Specification | Description |

| Material Types | Copper (Cu) Foil (Anode) and Aluminum (Al) Foil (Cathode) |

| Purity | High Purity (Typically 99.8% to 99.99% or higher) |

| Thickness | Ultra-Thin Gauges (Typically 6 µm to 50 µm), customizable |

| Surface Treatment | Electrodeposited or Rolled finish, often with specialized Roughened or Treated Surfaces for enhanced slurry adhesion |

| Form | Continuous Rolls or Pre-Cut Sheets (Customizable width and length) |

| Key Function | Efficient Electron Transfer and Mechanical Support for the active electrode material |

| Conductivity | Exceptional Electrical Conductivity |

Product Summary

The Current Collector is a vital, non-negotiable component in every modern battery and electrochemical device. Its function is twofold: to provide a stable, conductive path for electrons to move between the active electrode material and the external circuit, and to offer mechanical support for the fragile electrode coatings.

Our current collectors are manufactured to the highest standards of purity and dimensional tolerance, ensuring minimal internal resistance and maximum performance in your energy storage devices.

Primary Applications

New Energy Research (Lithium-ion Batteries):

Anode Current Collector: Copper (Cu) foil is used for the negative electrode due to its excellent conductivity and stability at the low potentials of the anode during charging.

Cathode Current Collector: Aluminum (Al) foil is used for the positive electrode due to its resistance to corrosion and stability at the high potentials of the cathode during charging.

Materials Chemistry & Functional Surfaces:

Electrode Substrates: Used as conductive backings for depositing thin films, functional coatings, or catalyst layers in R&D environments.

Flexible Electronics: Ultra-thin foils are critical components in the development of flexible and printed electronic devices.

Technical Importance in Batteries

The thickness and surface quality of the current collector are critical parameters:

Thickness: Using ultra-thin foil maximizes the amount of active material that can be packed into a given cell volume, directly increasing the energy density of the battery.

Surface: A controlled, slightly roughened surface is often engineered to improve the adhesion of the electrode slurry, preventing the active material from peeling off during manufacturing or prolonged cycling.

Ordering and Customization

Custom Thickness & Width: We supply foils in various precise thicknesses and can slit them to custom widths to match your specific cell design (e.g., cylindrical, pouch).

High-Temperature Options: Specialized foils (e.g., Nickel alloys) are available for applications requiring enhanced stability under high thermal stress.

Bulk Supply: Contact us for volume pricing and technical specifications on continuous foil rolls for pilot and industrial manufacturing.