Product description

PRODUCT INTRODUCTION

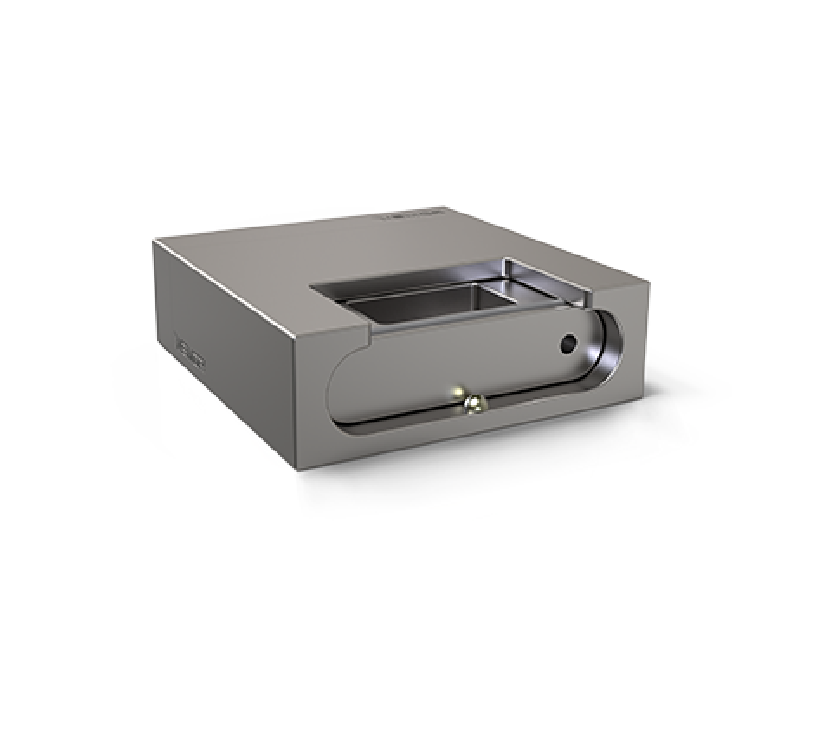

In-situ Transfer System for Vacuum Equipment

Many customers need sensitive samples not to be exposed to air during the whole process when using vacuum equipment. This device provides an ideal solution for the in-situ transfer sampling needs of all vacuum equipment. It not only ensures that sensitive samples are not contaminated by air during the whole process, but also enables the samples to be interconnected in-situ between various vacuum equipment. On the basis of in-situ transfer sampling, this device can also provide additional analysis functions, such as high and low temperature, charge and discharge, force curve, etc.

It ensures that sensitive samples are not contaminated by air and dust from the preparation in the glove box/ion milling instrument to the entry into the vacuum analysis instrument. The system can not only protect sensitive samples from contamination for a long time, but also has a simple structure, is easy to carry, and is suitable for long-distance transmission of samples.

It is suitable for all vacuum analysis instruments, such as electron microscope SEM, electron probe EPMA, x-ray photoelectron spectrometer xPS, scanning tunneling microscope STM, FOF-SIMS, ion milling instrument, etc.

PRODUCT FEATURES

In-situ transfer sampling

The system ensures that sensitive samples are prepared from the glove box/ion mill without contact with air or dust, and enter the vacuum equipment without pollution throughout the process.

Long-distance transmission

The system can not only protect sensitive samples from contamination for a long time, but also has a simple structure and is easy to carry, which is suitable for long-distance transmission of samples.

In-situ interconnection

After the vacuum equipment is analyzed, the vacuum is unloaded with inert gas, and the system automatically shuts down to protect the sample again, so that it can be transferred to the next vacuum equipment for analysis.

Multi-functional integration

In addition to in-situ sampling, sensitive samples can also carry out various accessory function tests, such as charge and discharge tests, high and low temperature tests, force curve tests, etc.