Product description

Product Name: High-Purity Spherical Nickel-Titanium (NiTi) Alloy Powder (Nitinol Grade)

Product Summary

Our Spherical Nickel-Titanium (NiTi) Alloy Powder, commonly known as Nitinol, is a premium material engineered for advanced applications in the Biomaterials, Medical Device, and Aerospace industries. NiTi is a Shape Memory Alloy (SMA) and Superelastic Material, possessing the unique ability to recover its original shape after severe deformation and exhibit extraordinary flexibility and kink resistance.

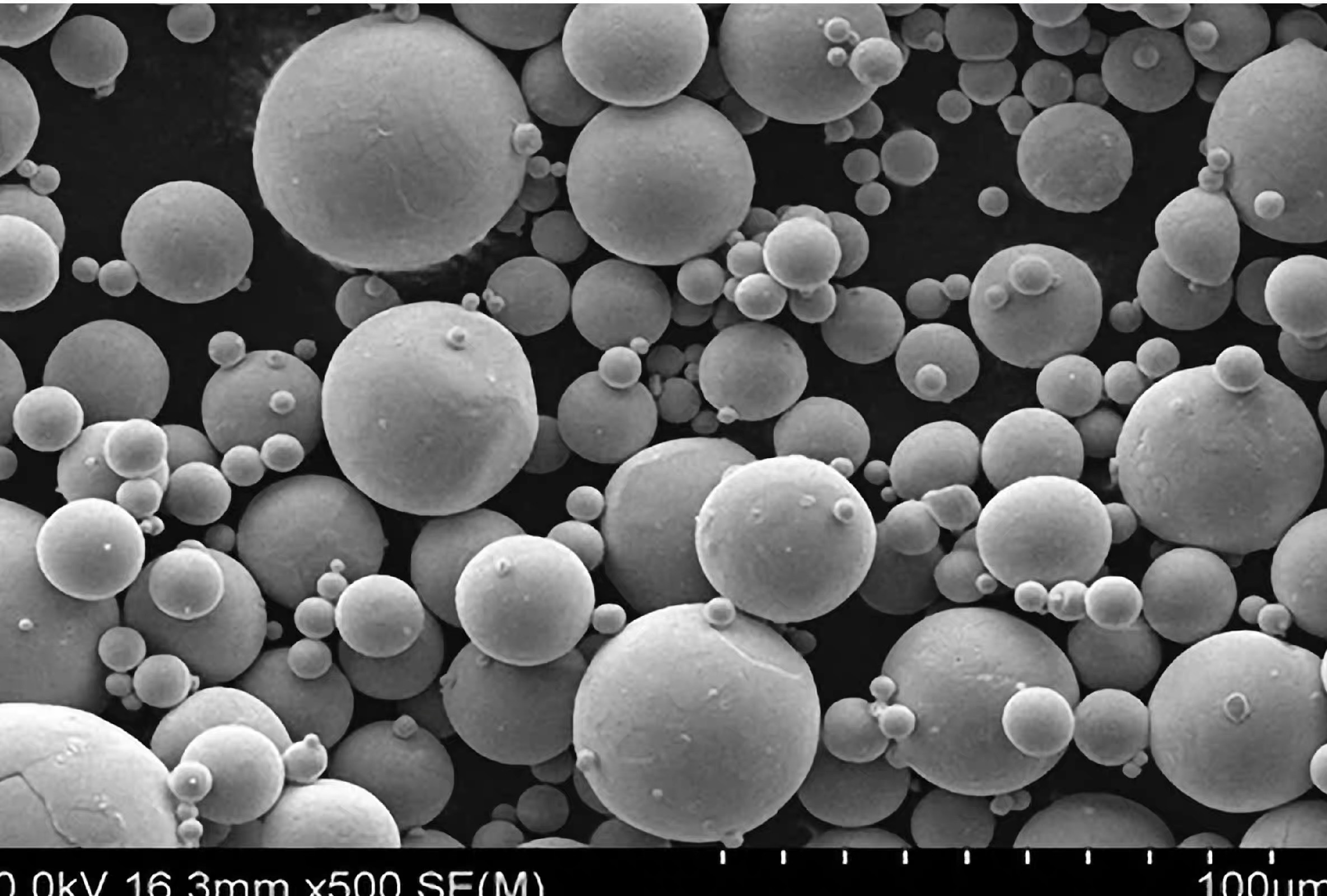

Supplied in a highly controlled spherical morphology, this powder is optimized for modern manufacturing techniques, particularly Additive Manufacturing (3D Printing) and Powder Metallurgy, ensuring excellent flowability, high packing density, and superior material homogeneity for the production of complex, high-performance parts.

Key Features and Specifications

| Feature Category | Specification |

| Material Composition | Near-equiatomic Nickel (Ni) and Titanium (Ti) (Typical range: Ni 50.6-51.0 at.%) |

| Key Properties | Shape Memory Effect (SME) and Superelasticity (SE) |

| Powder Morphology | Highly Spherical, Low Sphericity Deviation |

| Powder Purity | High Purity, Controlled Oxygen Content |

| Particle Size Range | Customizable (e.g., 15-45 $\mu$m for Laser Powder Bed Fusion, or larger) |

| Toxicity/Compatibility | Excellent Biocompatibility and Corrosion Resistance |

| Critical Temperatures | Precisely controlled Transformation Temperatures ($A_f$ and $M_f$) |

| Key Advantage | Minimizing Stress Shielding in implants due to superelasticity |

Primary Applications

Medical Devices & Implants (Biomaterials):

Stents and Catheters: Used in cardiovascular and neurovascular devices where superelasticity is critical for flexibility and deployment through tortuous anatomy.

Orthopedic Devices: Bone staples, fixation devices, and orthodontic wires that leverage the Shape Memory Effect to apply constant, gentle force or to self-deploy.

Additive Manufacturing (3D Printing): Creating custom, porous scaffolds and complex lattice structures for bone replacement or tissue engineering.

Aerospace & Robotics:

Actuators: Utilizing the Shape Memory Effect for lightweight, solid-state actuators (non-hydraulic/pneumatic) in space mechanisms and morphing structures.

Vibration Damping: Applications requiring high damping capacity, where the superelastic behavior can absorb mechanical energy.

Advanced Powder Metallurgy:

Sintering and Hot Isostatic Pressing (HIP): Used to consolidate complex-shaped parts with controlled porosity and high dimensional accuracy.

Technical Significance (Shape Memory & Superelasticity)

Superelasticity (SE): At body temperature (or application temperature), the material can undergo significant, non-linear deformation (up to $\sim$8%) and recover instantly upon unloading. This is due to a stress-induced phase transformation (Austenite to Martensite), which is key for kink-resistant surgical tools.

Shape Memory Effect (SME): When deformed at one temperature (Martensite phase) and subsequently heated above its Austenite Finish ($A_f$) temperature, the material recovers its pre-deformed shape, providing a strong actuation force.

Our high-quality spherical powder ensures that these phase transformation properties are consistently maintained throughout the final manufactured part, delivering unparalleled performance reliability.